- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Machine Clamp Tonnage Calculator For Polypropylene.

Correct Clamp Tonnage

Using a clamp tonnage calculator is a requirement for machine selection.

But what is the right clamp tonnage for producing a particular part?

In injection molding, finding the right tonnage can be tricky. Just because a moulding machine can produce a clean looking part without flash it doesn’t mean the clamp is enough.

For any particular part, there are a range of clamp tonnages than can produce parts that appear to be ok.

But what about the weight?

The correct tonnage will produce parts to the target weight consistently over an extended period of time. This is assuming that the process parameters have been setup correctly and optimized so that consistent fill times are maintained and hold pressure is not excessive.

If process parameters are not optimized then tonnage will need to be higher than is necessary. This uses extra electrical energy and increases the rate of wear in the mould and machine.

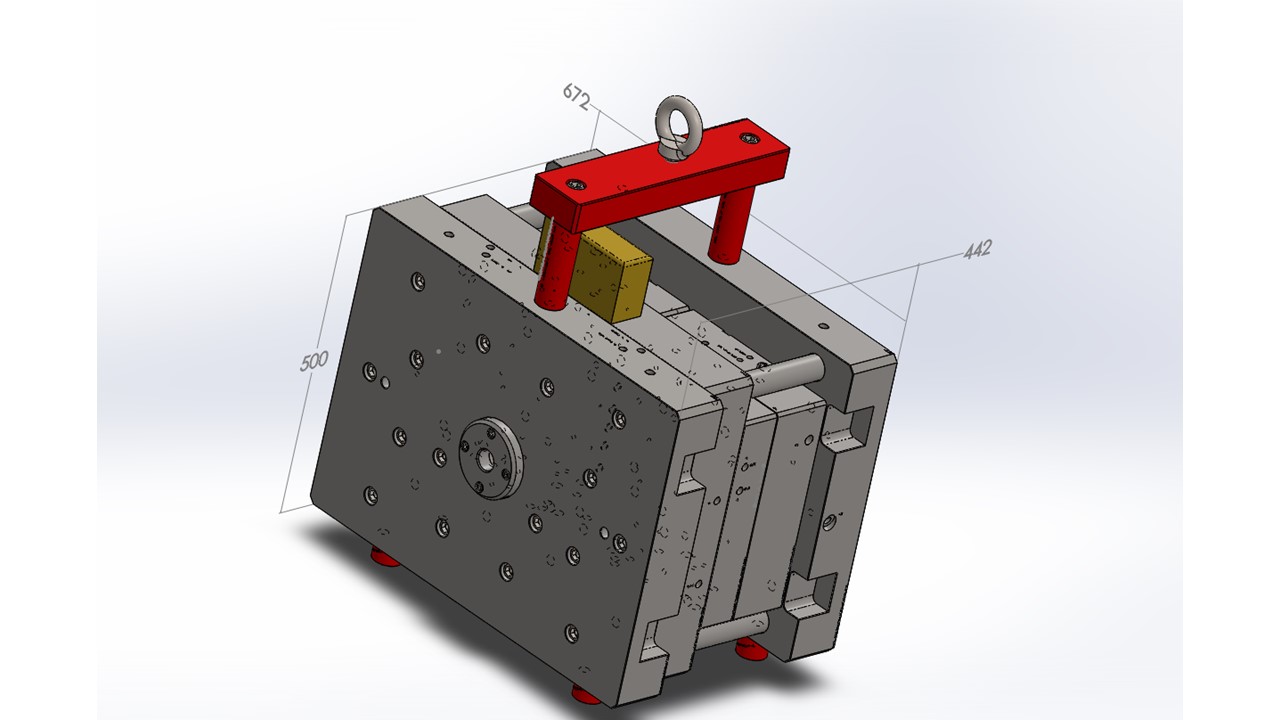

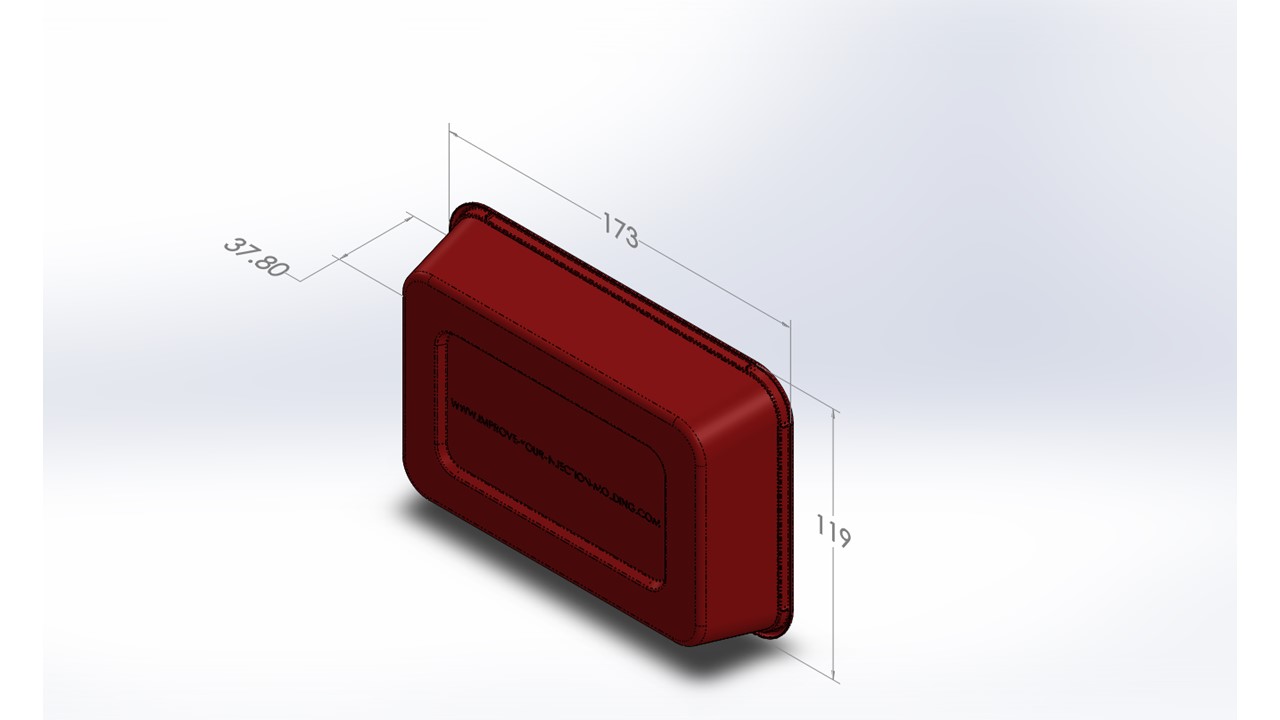

Discounted Mould Design For Sale

500ml Thinwall Disposable Food Tub 16.5 Grams

Clamp Tonnage Calculator

Use the following calculator to get an estimate of the tonnage required to mould a rectangular or round part. This calculator is to be used as a guide and the results are not guaranteed. For a more accurate calculation contact your moulding machine supplier.

| Square & Rectangular Parts:(mm) | Round Parts:(mm) | ||

| Length: | Diameter: | ||

| Width: | |||

| Max Flow Length From Gate: | Max Flow Length From Gate: | ||

| Wall Thickness: | Wall Thickness: | ||

| Number of Mold Cavities: | Number of Mold Cavities: | ||

| Material Flow Index (MFI): | Material Flow Index (MFI): | ||

| Answer: Metric Tons | Answer: Metric Tons | ||

Click here to read about our Mold Design Services

Return from Clamp Tonnage Calculator to Plastic Injection Molding Machine Selection