- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

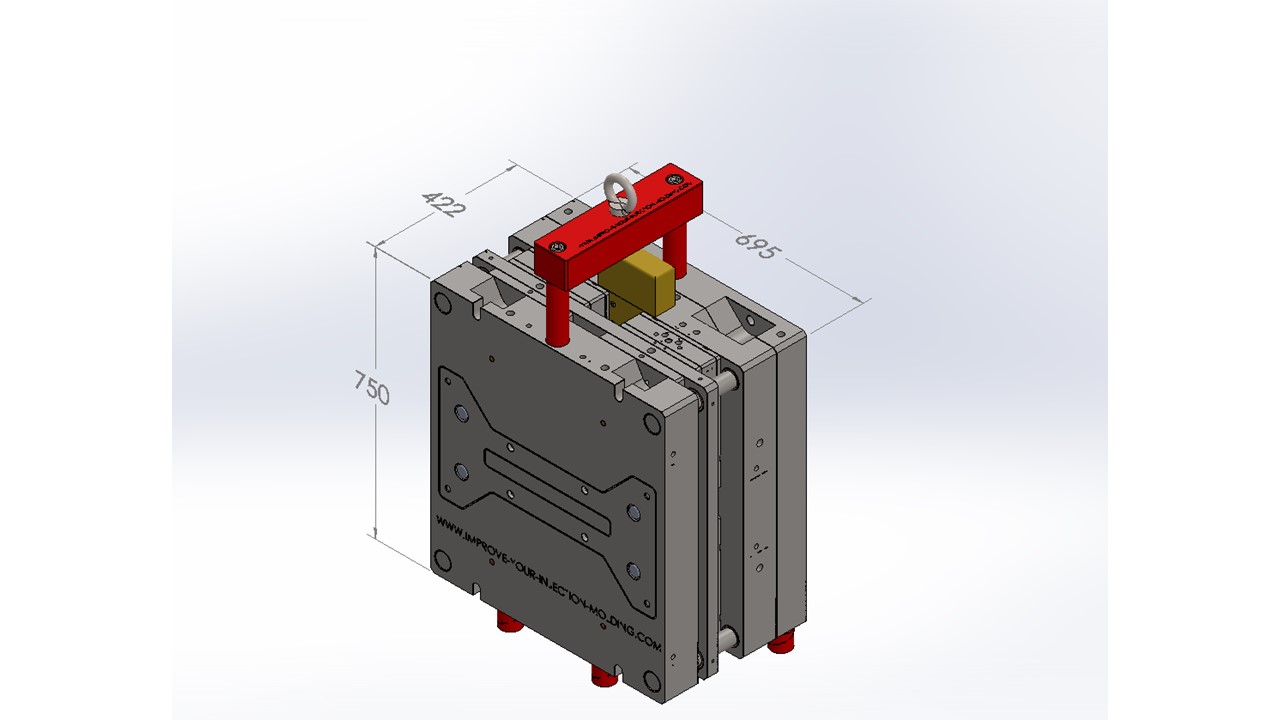

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Plastic Injection Molding Site Blog

The Plastic Injection Molding Site Blog is my mini-journal about Injection Molding.

It...

- lets you know when any new postings appear (like brief comments and suggestions on how to improve part quality, productivity and operational efficiencies using current technology and know-how)

- lets you know when any new web pages appear.

To subscribe to my Injection Molding Site Blog (no e-mail address necessary), RIGHT-click on the orange RSS button and then copy-and-paste the URL of this site's RSS feed into your RSS reader. OR...

Or click on the Google, My Yahoo!, My MSN, or Bloglines button if you keep a personalized home page there. Follow their instructions.

Once you start you will be amazed at how RSS brings your world to you.

Tooling Dept.

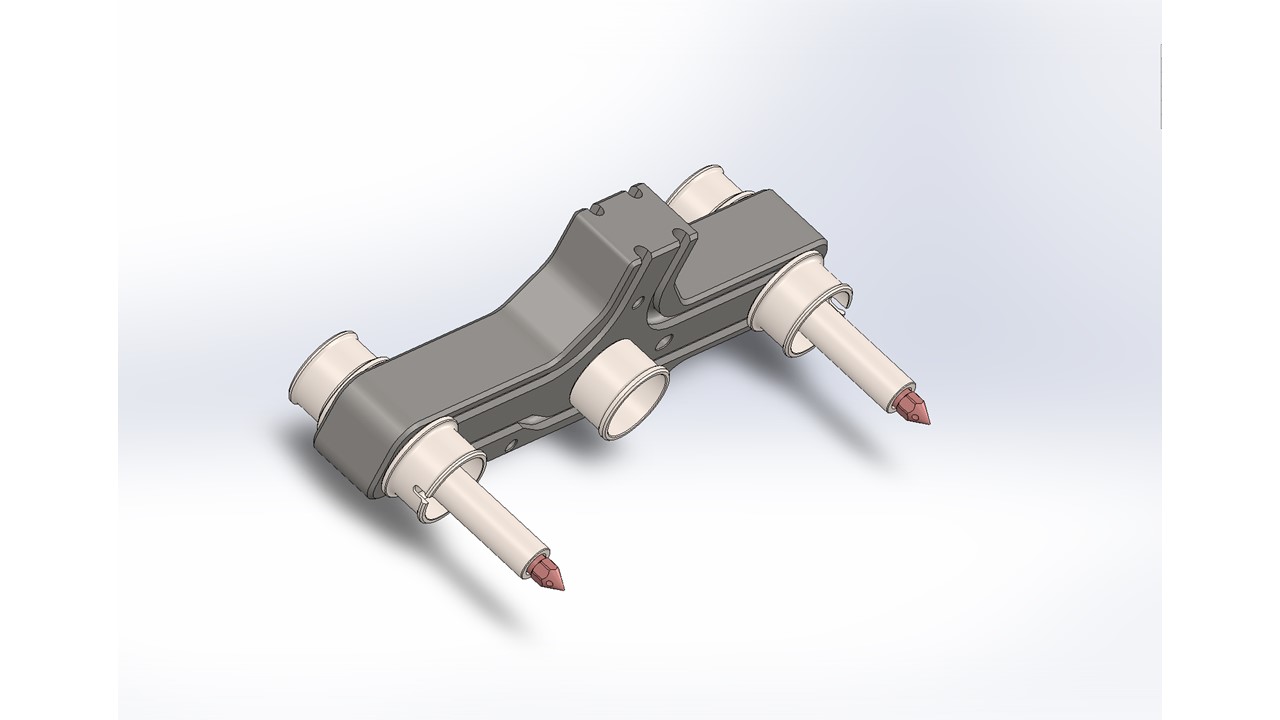

I have a 3 plate mould with 4 cavities and an angular slider in each cavity, at less than 50k shots the slider breaks, What can i do to improve the slider

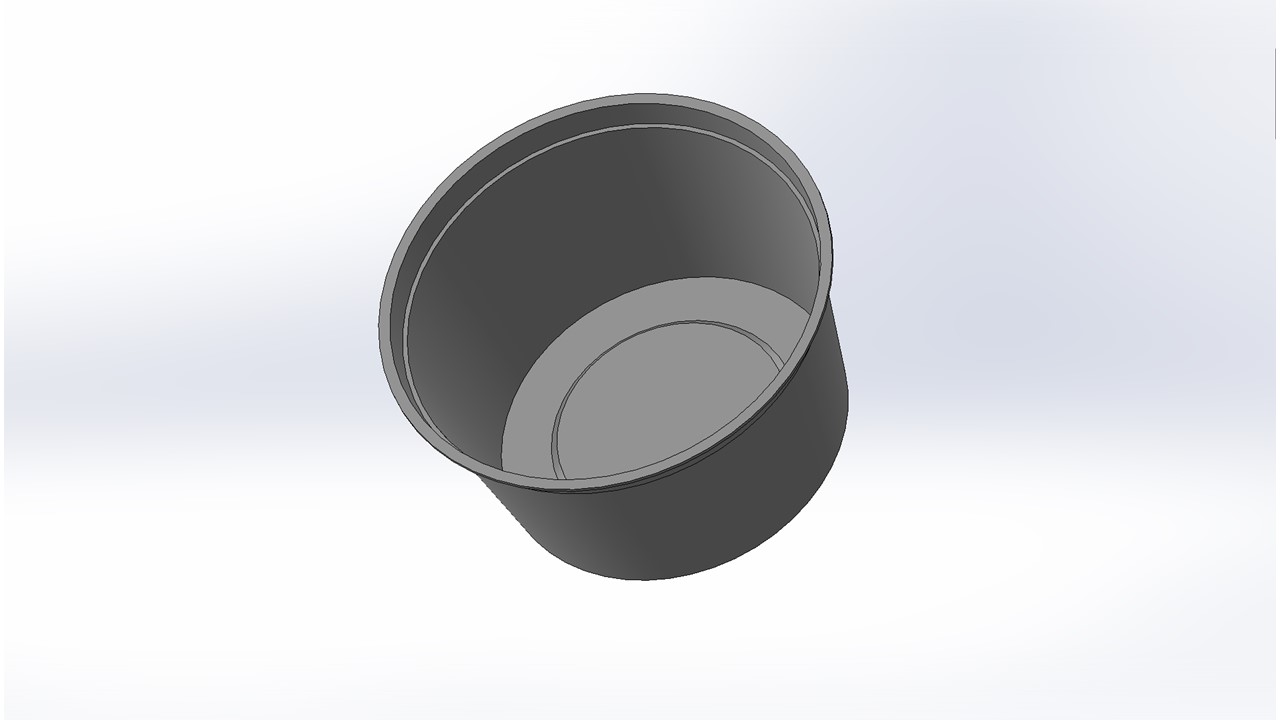

Ultra thin wall injection molding-Light weighting

Want to reduce your plastic part weight. Click here to see an example of how to light weight your part design using ultra thin wall injection molding.

Continue reading "Ultra thin wall injection molding-Light weighting"

Uneven Wall Thickness in Injection Molding

If you are wrestling with uneven wall thickness in injection molding then we might have the anwers for you

Continue reading "Uneven Wall Thickness in Injection Molding"

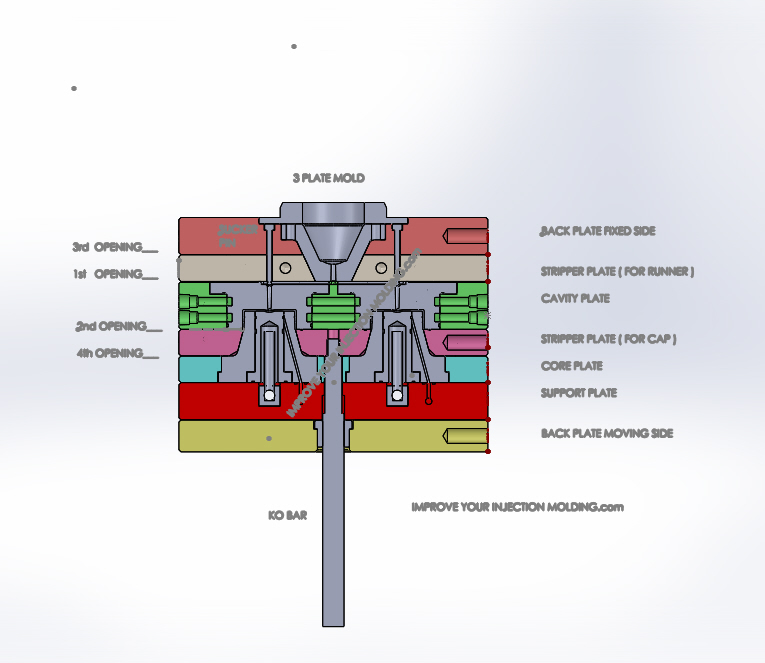

3 Plate Mold Design For Injection Molding

Learn how to design a 3 plate mold and when to use a 2 plate mold design.

Continue reading "3 Plate Mold Design For Injection Molding"

Learning Injection molding design

when wearplate is designed, is it necessary that there should be a very small gap between the core and cavity side of the mold right where the wearplate

Isolate plates

Where is better to put isolate during mold design? inside mold (between clamp plate and cavity plates) or outside? (after clamp plate) Can be an important

mold size calculation

From part size & number of sliders,undercut how to calculate tentative mold size?

What’s would be the extra material to keep at the matching area of core and cavity inserts

1What’s would be the extra material to keep at the matching area of core and cavity Inserts 2. How to provide spacer lengths interms of ejection length

Injection Molding Training for Thin Wall Packaging Parts

Start making & processing thin wall molds at a profit with injection molding training.

Continue reading "Injection Molding Training for Thin Wall Packaging Parts"

Support pillars

Is there any specific calculation for using a particular size of support pillars and it's placing?

Setting Hold Time and Hold Pressure to Run an Optimized Process

Learn how to make quality parts without spending money

Continue reading "Setting Hold Time and Hold Pressure to Run an Optimized Process"

3D Rapid Prototyping in Injection Molding

Learn how 3D rapid prototyping benefits the injection molding industry

Continue reading "3D Rapid Prototyping in Injection Molding"