- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Injection Mold Designer for Thinwall Packaging Parts– What Makes Him Competent?

Do you want a thinwall injection mold designer who knows what works rather than what should work?

In plastic injection molding, a competent mold designer understands the difference between theory and practice so that he can deliver a design that will be capable of producing quality parts at the expected cycle time for the estimated production quantity.

The mold will be easy to build, start up and maintain.

How Does He Do This?

A competent designer will know what questions to ask and who to ask. The first people to talk with are the plastic part designers and the reason is simple: often plastic parts have not been designed for manufacture. Lack of draft or radii, uneven wall thickness will cause constant quality problems and long cycle times. Check for these issues first.

The second people to talk to is the injection molder. They are the end user of the mold so it should be designed in a way that makes it easy to set up, maintain and use. What’s more, they have years of experience producing plastic parts from a variety of materials and mould designs so they have valuable insights into what works.

Other questions should relate to the molding machine specifications such as tie bar distance, minimum mould opening stroke, location ring diameter, number of air valves on machine and water fitting thread sizes and so on.

Thirdly, he should talk to the mold maker and get his feedback into design. He should have a good idea of successful mold designs if he has taken the time to find out from his injection molding customers what designs work.

What Qualities Does A Thinwall Designer Need?

A competent injection mold designer should have the following experience and skills:

- Hands on injection molding experience

- Hands on mold making experience

- Plastic part design experience

- Understand Design for Manufacturing and Assembly principles

- Experience with mold design software

- Sound technical knowledge

- Experience dealing with customers

- Flexibility

- Be a team player

- Willingness to learn

- Ability to listen

A person with these qualities is in a unique position to achieve a successful mold design.

Technical Knowledge Requirements

People who work in an injection mold design company should have a sound knowledge of the most important aspects of mold design.

Cooling Design

One of the most important aspects of mold design is the cooling system. It plays a critical role in the final part quality and productivity. In the molding process, long cooling times mean long cycle times. Short cooling times mean short cycle times.

Designing the right cooling system for the part will ensure optimum cycle times – the cooling time should not be limited by the cooling design it should be limited by the part design. Thicker wall sections will naturally have longer cooling times.

With proper cooling design, the mold will be capable of cooling down during the mold opening and closing stages. That means that the water channel distance from the molding surfaces and the distance between the cooling channels is critical.

Runner Design

Runner design includes both cold runner and hot runner designs. Which is better? Both have their place and the one chosen depends upon the part design, molder capabilities, production quantities and mold price.

High volume, thin walled parts such as food containers use hot runners. To be competitive in thin wall high production quantities are necessary so fast cycle times and high cavitation is required. Hot runners can only achieve this.

To design molds for thin walled parts an injection mold designer who specializes in this type of tooling is required. Do not use a designer who only has experience with general-purpose moulding.

Cold runners are suitable for single cavity or multi cavity moulds with low to medium production requirements. Cold runners make colour change quick and easy as the runner is ejected between each cycle. Hot runners take time to change color.

Ejection Design

Part quality and productivity will suffer with a poorly designed ejector system. A good design will produce parts consistently and at optimal cycle times.

The mold will run fully automatically without the need for human intervention. This means the molder is operating efficiently and able to stay competitive by delivery on time and producing at minimal cost.

Common ejector systems use ejector pins, stripper rings or air pressure. The system used depends upon the part design, plastic material, mold price, production quantity requirements and machine capability.

Mold Rigidity

A weak mold will cause part quality problems immediately. Mold cavity size must be large enough to ensure it can withstand injection pressure and clamp tonnage. Plate thicknesses need to protect the mould against excessive platen deflection and mould wear.

Minimum mold sizes as specified by some molding machine manufactures need to be treated with caution.

Interlocking between fixed and moving sides should be strong enough to maintain alignment under injection pressure.

The result is a mold that will last for the intended production life.

Venting

Correct venting size and location is critical to the production of quality parts. Without it you will get burn marks, bubbles, voids and uneven filling patterns which will result in rejects. Vents should be placed at the last point to fill.

Vents frequently get blocked so it’s important that the injection mold designer allows for easy cleaning of the vents in the molding machine so downtime is kept to a minimum.

Mold Material

There are many different types of materials that can be used to construct a mold. Common materials are tool steels, mild steels, copper alloys and aluminium. The material used depends on the mold price, mold life, part design, part material and molding conditions.

Moulds made for low volume part quantities can use softer materials such as aluminium as these are cheaper and easier to work with. Molds made to produce millions of parts require through hardened steels such as H13 which are more expensive and harder to make.

Using the correct material will ensure you get good mold life without having to spend any more money than required.

Additional Comments

The fact is, if you would like to save thousands of dollars by avoiding quality issues and slow cycle times then get the right injection mold designer.

Most importantly, a good tool design will only work if:

- Part design is correct

- Part plastic material selection is correct

- Mold making is correct

- Molding machine is compatible with mold and in A1 condition

- Water system has adequate flow and pressure to the mold

- Air compressor has adequate flow and pressure to the mold

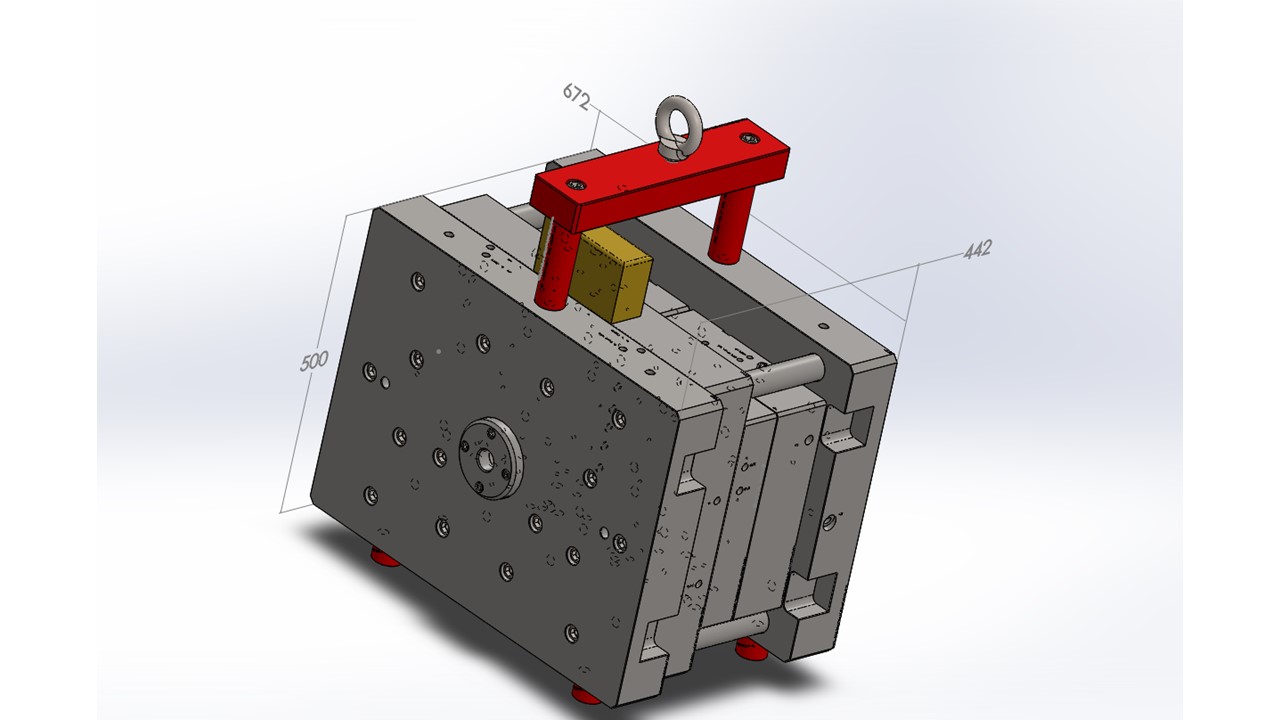

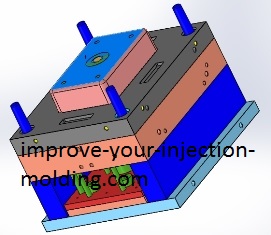

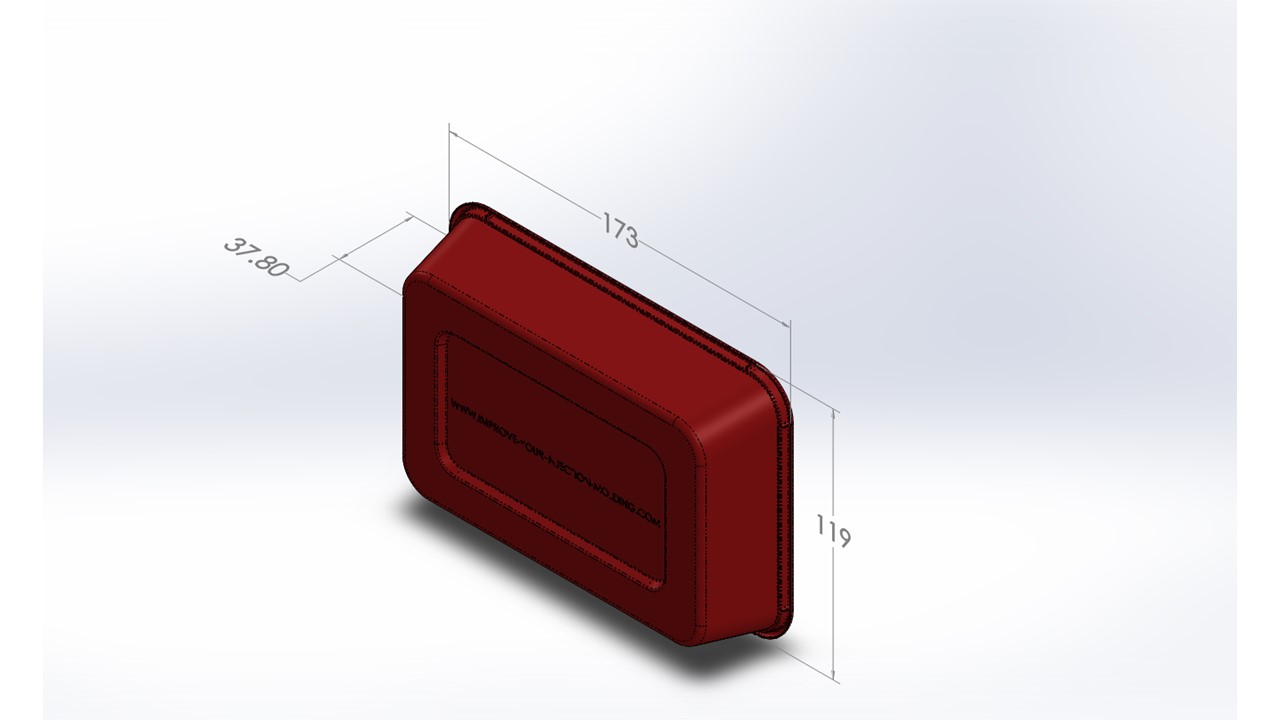

Discounted Mould Design For Sale

500ml Thinwall Disposable Food Tub 16.5 Grams

Return from Injection Mold Designer to to Injection Mold Design

Return from Injection Mold Designer to Improve Your Injection Molding Home Page