- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Injection Molding Consulting Service

Troubleshooting Quality & Cycle Time Problems

Injection molding consulting service specializing in troubleshooting part quality and cycle time problems for plastic parts with thin walls. Questions about general purpose moulding problems are also welcome.

Read the case studies below or click here to skip down to the contact form.

Case Studies

Example #1 (Quality Issue)

2 Litre Ice Cream Container (Thin Wall Molding)

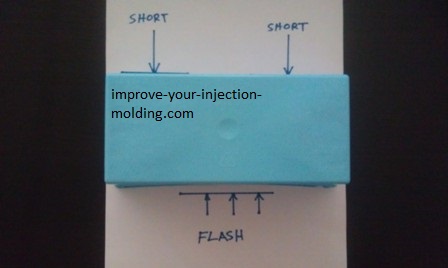

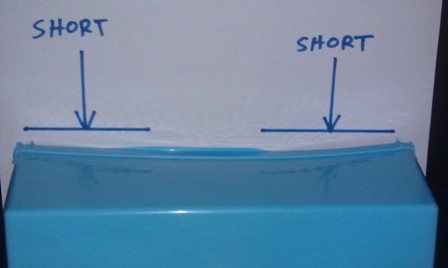

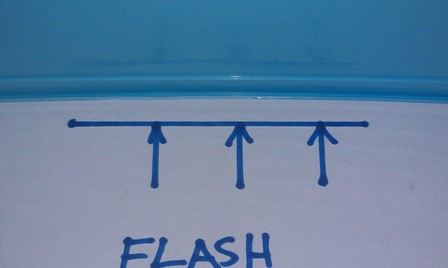

Problem: Flashing and shorting at the same time. See figures 1,2 &3,

Wall thickness 0.60mm (0.024 inch)

Length 280mm (11.0)

Width 140mm (5.5)

Height 95mm (3.7)

Material: polypropylene copolymer

Weight 71.4 grams

Single cavity mould

Solution: After checking the mould stripper plate and interlocking fitting dimensions several times, it was found that the machine was at fault.

The fixed side platen had a 0.03mm (0.0011) impression hobbed into it by another mould which was only slightly smaller than the 2 litre container mould in terms of the length and width of the back plate.

The impression allowed the mould to flex into this 0.03mm area under injection pressure causing the flash since there was no support behind the mould.

Shim was placed between the fixed side platen and the mould which eliminated the flash.

Example #2 (Quality Issue - incorrect machine selection)

PET Box (general purpose molding)

Problem: Unmelted pallets in the part.

Wall thickness 2.0mm (0.079 inch)

Length 110mm (4.3)

Width 110mm (4.3)

Height 255mm (10.0)

Material: PET

Weight 342 grams

2 cavity mould

Solution: The PET Box was originally installed in a 300T Haitian moulding machine and the injection unit was fitted with a general purpose screw.

The screw was not capable of plasticizing each shot consistently within the required cycle time so the mould was moved to a Husky machine designed to manufacture PET preforms at short cycle times. This machine did not produce any parts with unmelted pallets so the original machine was fitted with a new screw designed to plasticize PET resin.

This was a case of incorrect machine selection.

Example #3 (Cycle Time Issue)

Rectangular Lid for 30 Litre Container

Problem: slow cycle time currently 21.4 seconds. Target 19.0 seconds.

Wall thickness 1.4mm (0.055 inch)

Length 410mm (16.1)

Width 325mm (12.8)

Height 35mm (1.4)

Material: polypropylene homopolymer

Weight 295 grams

Single cavity mould

Solution: Figure 4 shows the build up of brown residue in the water cooling channels in the core side of the mould. The build up is thick and reduces the cooling effect on the part.

The build up was removed manually by hand which reduced cycle time to 19 seconds.

That’s a 10% increase in productivity which translates into tens of thousands of dollars in extra sales per year for just a few hundred dollars investment.

Example #4 (Mold Quality Issue)

Rectangular 35 Litre Storage Container

35 litre storage container

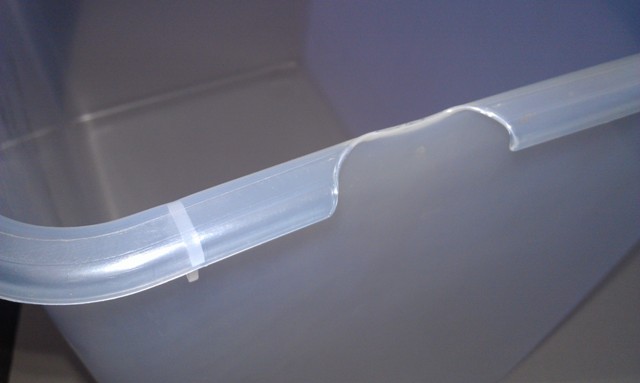

35 litre storage containerProblem: Uneven fill causing shorting on one side

Wall thickness 2.0mm (0.078 inch)

Single cavity mould.

Solution: The worn interlocking surfaces between fixed & moving sides allowed misalignment between the core & cavity which caused the filling pattern in the cavity to change: the thicker sides filled first and the thinnest side required higher than normal hold pressure in order to make a complete container.

Extra clamp tonnage was also required to stop flash which increased the rate of mould wear.

The variation in wall thickness gradually become worse over time resulting in an increasing rate of short shots.

The issue was fixed by adding shim behind the removable wear plates of the interlocking surfaces which centralised the core & cavity ensuring even wall thickness on all 4 sides of the storage container.

This Injection Molding Consulting Troubleshooting Service can achieve the same result for you too.

Fill out the form below:

If you have cycle time problems or part quality issues such as flash, short shots, black specs, splay, jetting, warping, sink, distortion, air entrapment, weld lines, inconsistent shrinkage rates or part failures then contact us using the following form.

While specializing in troubleshooting quality and cycle time problems for Thin Wall parts, questions about general purpose moulding problems are also welcome.

We will reply to you shortly to setup a time to communicate by telephone, Skype or email with the purpose of solving your quality issue.

Right-click here to download these case studies in PDF format

You will need Adobe Reader (the latest version is recommended) installed on your computer in order to open and read this e-book. You can download Adobe Reader here (a new window will open so you can download it without leaving this page).

If you want to open the file in your browser window, just click on the link (not all browsers have this feature). However, if you want to download the file to view later, then right-click on the link and choose "Save Target As" or "Save File As." Then select where you want to save the file on your hard drive.

Once you have saved the file, locate where you saved it, and double click to open it.

In order to print, open the downloaded file, and select the "Print" option from the e-book menu.

Return from Injection Molding Consulting to Plastic Injection Molding Machine Selection