- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Custom Mold Design Services

For Thin Wall Packaging Parts

Let Improve-Your-Injection-Molding mold design services take your business to the next level - its the easy way to get what you want.

Specializing in:

- 2,4 and 6 cavity straight face mould design for Thin Wall parts

- 2+2 and 4+4 stack mould design for Thin Wall parts

- Product development for Thin Wall parts including In Mould Labeling (IML) requirements

Discounted Mould Design For Sale

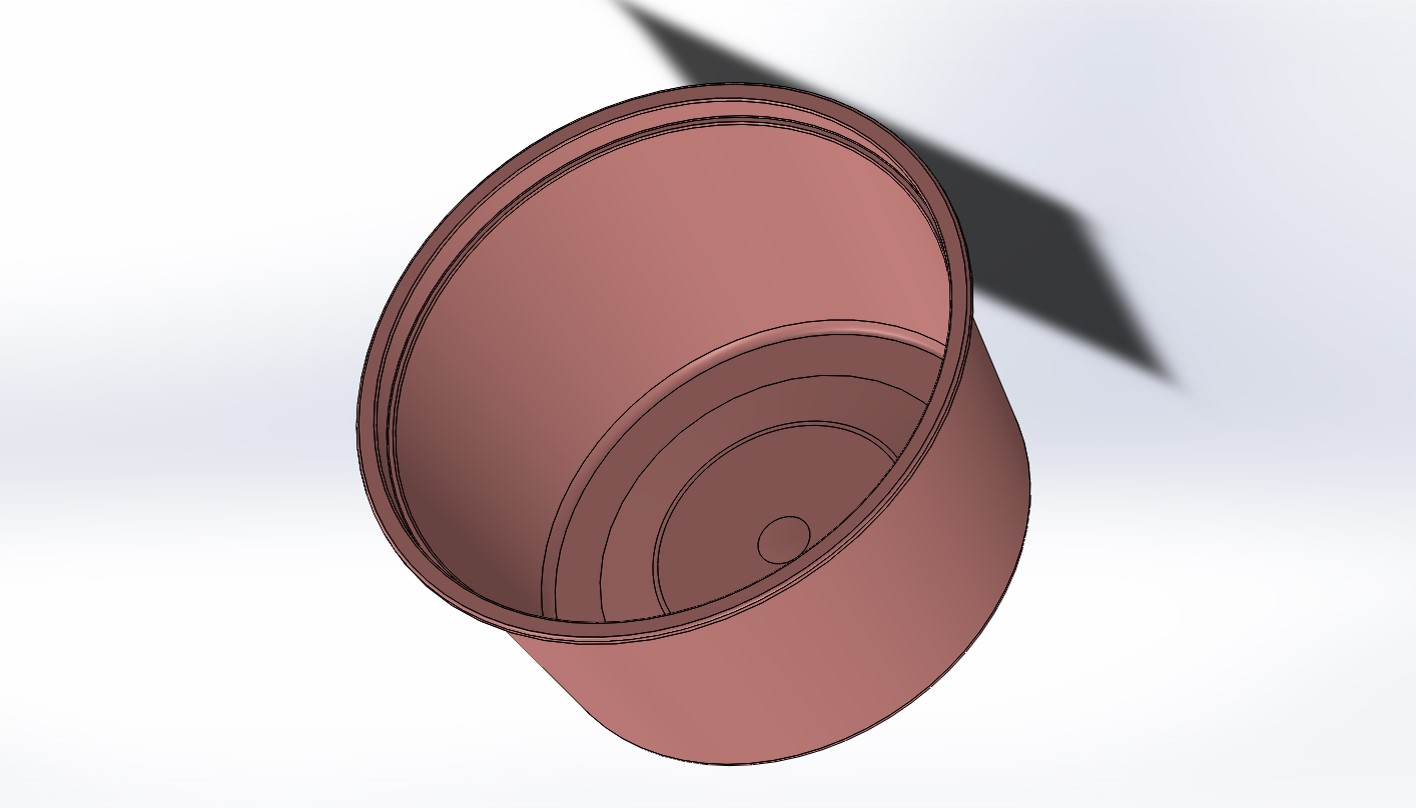

500ml Thinwall Disposable Food Tub 16.5 Grams

Video Example 1

Scroll down to see Stack Molds

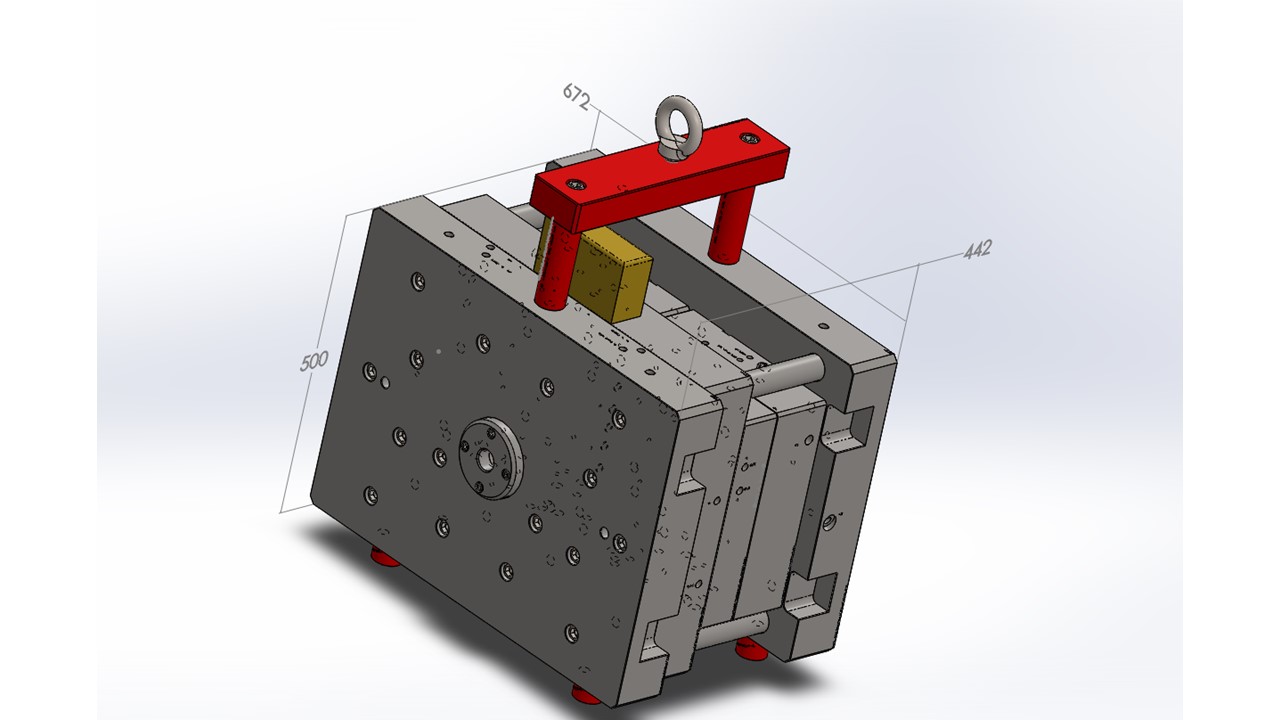

Thin wall 500ml Food Container 4 cavity hot runner mold tool.

Food container details: (see Figure 1)

Weight: 13.0 grams

Wall thickness: 0.45mm (0.0177 inch)

Material: PP homo polymer

Cycle time: 3.9 seconds (free drop)

Ejection type: 4 individual stripper plates

Annual number of cycles capability: 7 million

Annual production capability: 28 million (4 cavities)

This mold was designed by Improve Your Injection Molding & built to the Society of Plastics Industry (SPI) Class 101 mold classification.

Figure 1

Figure 1

Example 2.

Thin wall Disposable Rectangular 750ml Tub 2+2 Stackmold

Part weight: 22.5 grams

Wall thickness: 0.55mm (0.022 inch)

Material: PP homopolymer

Cycle time: 6.6 seconds (robot takeout)

Hot tip hot runner

Annual production capability: 17.5 million (4 cavities)

Machine clamp requirement: 300T

Example 3.

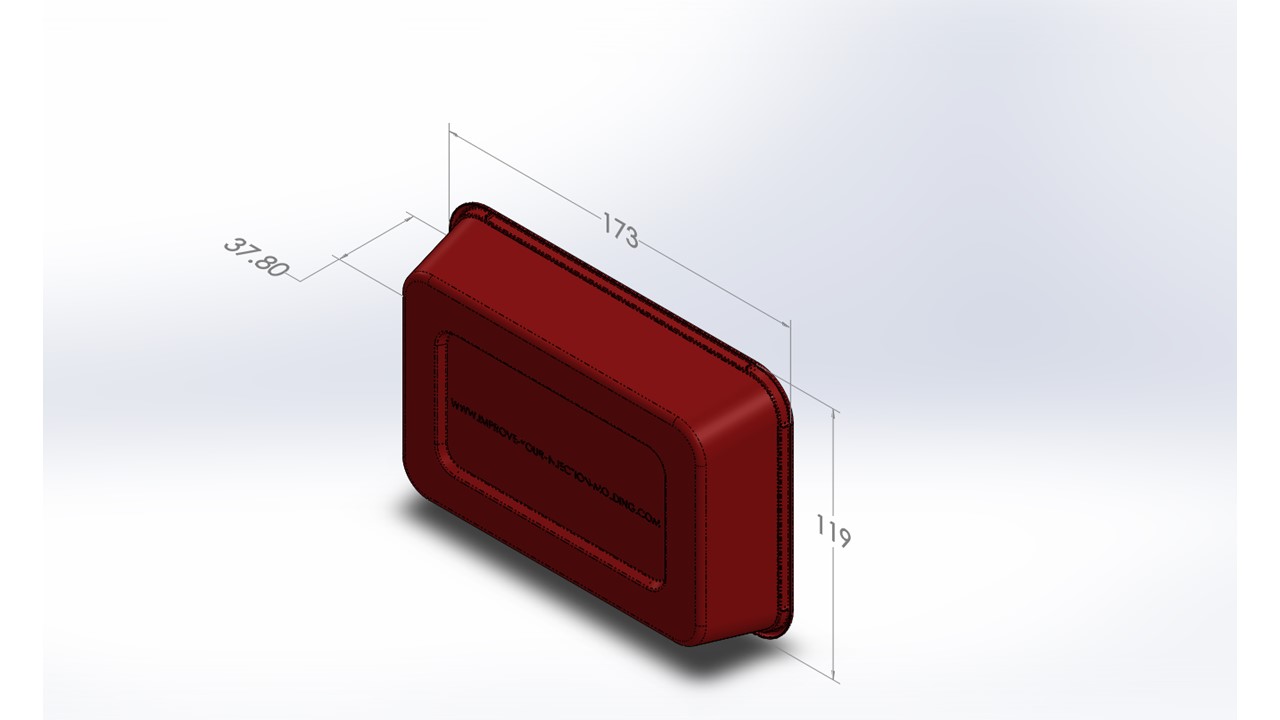

Thin wall Disposable Rectangular Lid 2+2 Stackmold

Part weight: 12.4 grams

Wall thickness: 0.51mm (0.02 inch)

Material: PP homopolymer

Cycle time: 3.7 seconds (free drop)

Hot tip hot runner

Annual production capability: 30 million (4 cavities)

Machine clamp requirement: 250T

Example 4.

Thin wall Disposable Rectangular Lid 4+4 Stackmold

Part weight: 12.4 grams

Wall thickness: 0.51mm (0.02 inch)

Material: PP homopolymer

Cycle time: 5.0 seconds (robot takeout)

Hot tip hot runner

Annual production capability: 45 million (8 cavities)

Machine clamp requirement: 500T

Mold Design For Packaging Products Including Thin Wall

Thin wall products - Food containers, cups, plates, buckets & lids.

Polycarbonate Drinkware

Caps & Closures

Cutlery - fork, spoon & Knife

Storage Containers 5, 9, 12, 18, 20, 30, 40 litre

2 Shot Mold Design

Mold design outsourcing is becoming more common as the skills gap widens in the plastic injection molding industry.

If you are like many injection moulding & tool making companies you may be searching for the perfect blend of price, delivery time, quality and support.

If you are becoming frustrated in your search for the ideal mould design service then we might have the answer for you.

Get It Right The First Time

If we had found precision mold design services specializing in high volume products back when we did mold making for thin wall packaging, we believe it would have saved us 5 years of frustrations.

We are not exaggerating. It takes a lot of trial and error to work this stuff out and we suggest, if at all possible, you take the shortcut past that stuff and start doing what works.

To be able to injection mold tens of millions of quality parts consistently and at a profit not only requires knowledge of mold design but also knowledge in the other key areas of part design, machine selection & of course processing.

We can advise you in all of these areas.

If you are ready to take your business to the next level & get the mould designs that will help you achieve the results you want from your business then we invite you to scroll down to the contact form.

Mold Design Services for Molders & Toolmakers

This service is perfect for those injection molders who currently make their own molds & plan to light weight their products by manufacturing injection molds for thin wall packaging products and need help with mold design & machine selection.

This service is also ideal for toolmakers (mold builders) who plan on building moulds for thin wall packaging products (with or without IML) or just need extra design capacity.

Existing Quality Issue

If you have an existing quality issue such as wall thickness variation & want to avoid this issue on your next mold design then we can help you!

Training for Mold Designers

We can also train your mold designers to design thin wall moulds that work properly the first time. Do not waste time thinking you know what you are doing. You do not know what you do not know. Contact us to find out more.

Risk Free Approach

What do we mean by risk free?

If you get stuck during mold building, mold trialling or even during a production run, we will keep providing the necessary advice required for you to achieve the expected part quality and productivity levels at no extra charge.

Privacy Policy

We know how important confidentiality is to our customers so your information is safe with us. Click here to read more about our privacy policy (opens in a new window).

Example 5

Working Together as a Team

In order to get a design that will be compatible with your business it is critical that we get your input into the mould design.

Such things as expected annual quantity requirement, In-Mold Labeling requirement (IML), mold ejection method & water fitting size need to be discussed before mould design begins.

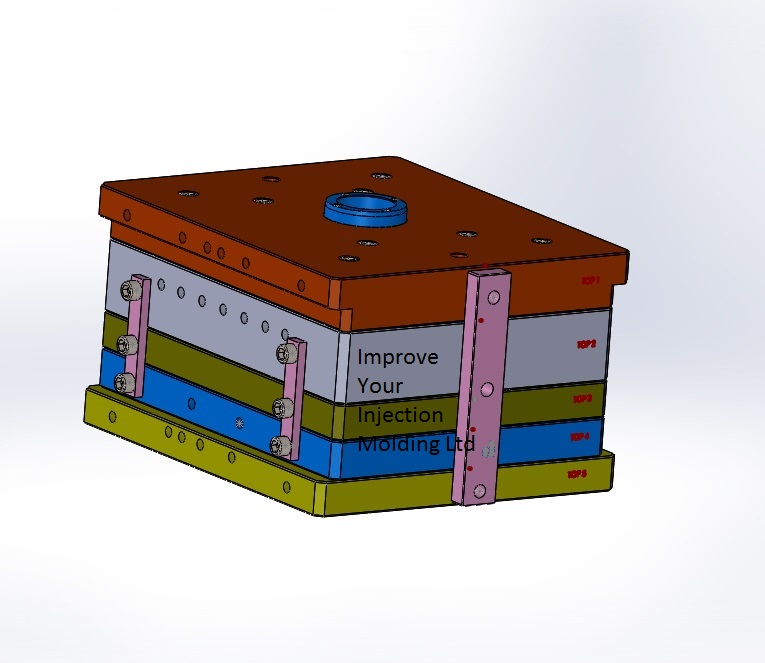

Example of mold assembly

Example of mold assemblyExample 6.

WuLiangYe Chinese Liquor 3 Piece Cap

16 cavity collapsing core mold

Part weight: 4.8 grams

Material: K-Resin

Cycle time: 13.7 seconds

Hot tip hot runner

Annual production capability: 33 million

Machine clamp requirement : 150T

Now's The Time To Contact Us

If you would like a quote for our design services for single cavity, multi-cavity hot runner molds or stack molds fill out the contact form below & we will contact you quickly.

We also do mold design for thick walled parts so contact us now!

Return from Mold Design Services to Plastic Injection Molding Machine