- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

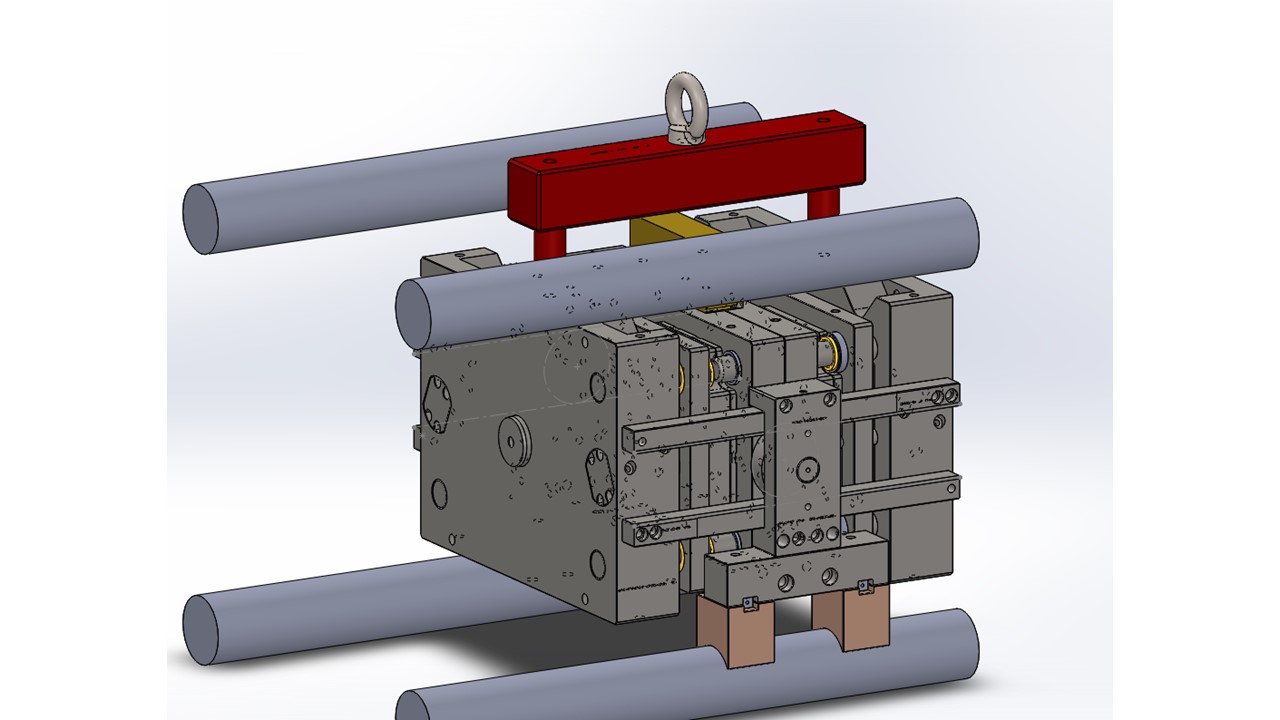

Stack Molds In Injection Molding

Stack molds might be for you if you have annual part quantity requirements in the millions like the thin wall food container in the video.

If you are looking to expand your injection molding business then they can save you hundreds of thousands of dollars in capital investment.

They almost double production capacity per machine.

They will save you buying extra machines and takeout robots. Click here to BUY our PROVEN MOLD DESIGNS for stack molds (opens in a new window).

2+2 DISPOSABLE LID STACK MOULD FOR SALE

2+2 DISPOSABLE LID STACK MOULD FOR SALE

Stack Molds Case Study

A 4 cavity mold is needed to satisfy new part quantity requirements. For a 500 ml container the existing 2 cavity mould is old and produces poor quality parts.

What are the options?

Replace existing mould with:

1. Two new straight face 2 cavity molds

2. One new straight face 4 cavity mold

3. One new 2+2 stack mould

Option 1 will need an additional 260t machine assuming the existing 260t machine can be used.

Option 2 will need a 550t machine which will cost a lot more than a 260t machine and use up a lot more floor space.

Option 3 might be able to use the existing machine saving you the cost of a new 260t machine. Even if it can’t be used, still only one new machine is required to run 4 cavities and the existing machine can be used for another mould.

So it is clear that the best option from a capital investment point of view is option 3 as production is almost doubled with only one machine. It also saves one robot which can easily cost $50,000 each.

Even better, the price of a 2+2 stack mould is almost the same as mold options 1 or 2 above. So from a mould cost point of view it makes very little difference which mould configuration is used.

Common Misconceptions About Stack Molds

1.They are harder to set up

Setting up a stack mould in a molding machine is a step by step procedure like any mould. The only difference compared to a straight face mould is the side gear mechanism. This will take one person 30 minutes to set up but there is nothing complicated about it- its just another step by step procedure and very easy to do.

2.They are harder to maintain.

Stack molds are just as easy to maintain as straight face moulds. Just keep the shutoff surfaces clean and free of residue. Clean behind stripper inserts on a regular basis as well. Easy access to cleaning is the key. But like any mold if it is not designed for maintenance then it will be difficult to maintain.

3.Grease is needed on all moving parts.

Stack molds have a side gear mechanism which allow the mold to open and close smoothly. The mechanism most commonly uses racks and gears to connect the mold together. It is a common occurrence that die setters and process technicians will apply grease to the racks and gears. The problem with grease is that it can attract and hold foreign material which will be crushed in between the gears and damage them.

In fact, grease is not required because the racks and gears are heat treated so that wear between these parts is virtually eliminated. Properly heat treated parts will never pick up or score.

Clamp Tonnage Requirements

The clamp tonnage required for a stack mould is about half the tonnage required for a straight face mould with the same number of cavities. For example, if a 4 cavity mould requires 300 tons clamp force then 2 +2 stackmould requires about 150 tons plus 15%(for the same part). Check with your machine supplier for a more accurate calculation.

Moulding Machines

Stack moulds can run in normal injection moulding machines provided they satisfy the following criteria:

- There is sufficient mold space

- There is sufficient opening stroke

- There is sufficient shot size barrel capacity

- There is sufficient injection speed

- Machine shut off pin (optional)

If buying a new machine for a stack mould then buy one with the extended tie bar option so that there is sufficient mold space to design a strong mould that will last.

Trouble Shooting

Stack molds will be problem free provided they are properly maintained. Over time however, as the mold starts to wear, balancing issues will become evident especially in thin wall molding.

The secret to overcoming balancing issues is to have a mold design that allows easy access to certain mold components. In other words, the balancing issues can be fixed without having to remove the entire mold from the moulding machine. So if stripper plates are part of the mould design they will be able to be removed, surface ground and then replaced in as little as 30 minutes.

The Fountain Effect

Because of the design of a stack mold hot runner system there is a natural imbalance between the front and back cavities during first stage filling.

The front cavities fill before the back cavities which can result in quality problems such as weight differences, flashing and short shots.

The mould design should make allowances for the fountain effect so that easy adjustments can be made during first mould trials. One way to do this is by reducing wall thicknesses on the front cavities.

Disadvantage

The disadvantage of a stack mould is that they are not as flexible as straight face moulds. In other words, straight face moulds can usually fit into several different moulding machines within an injection moulding company but a stack mould will usually only fit into one or 2 machines because of mould space requirements. So if the moulding machine breaks down then production stops from the stack mold.

Return from Stack Molds In Injection Molding to Plastic Injection Mould Making