- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Uneven Wall Thickness in Injection Molding

If you suffer with uneven wall thickness in injection molding then you are not alone.

Its very common in injection moulding applications especially in parts with thin walls.

250ml Tub 0.45mm wall thickness

250ml Tub 0.45mm wall thicknessThe 250 ml tub had wall thickness variation of over 0.1mm but with new mould design variation was less than half to 0.03mm.

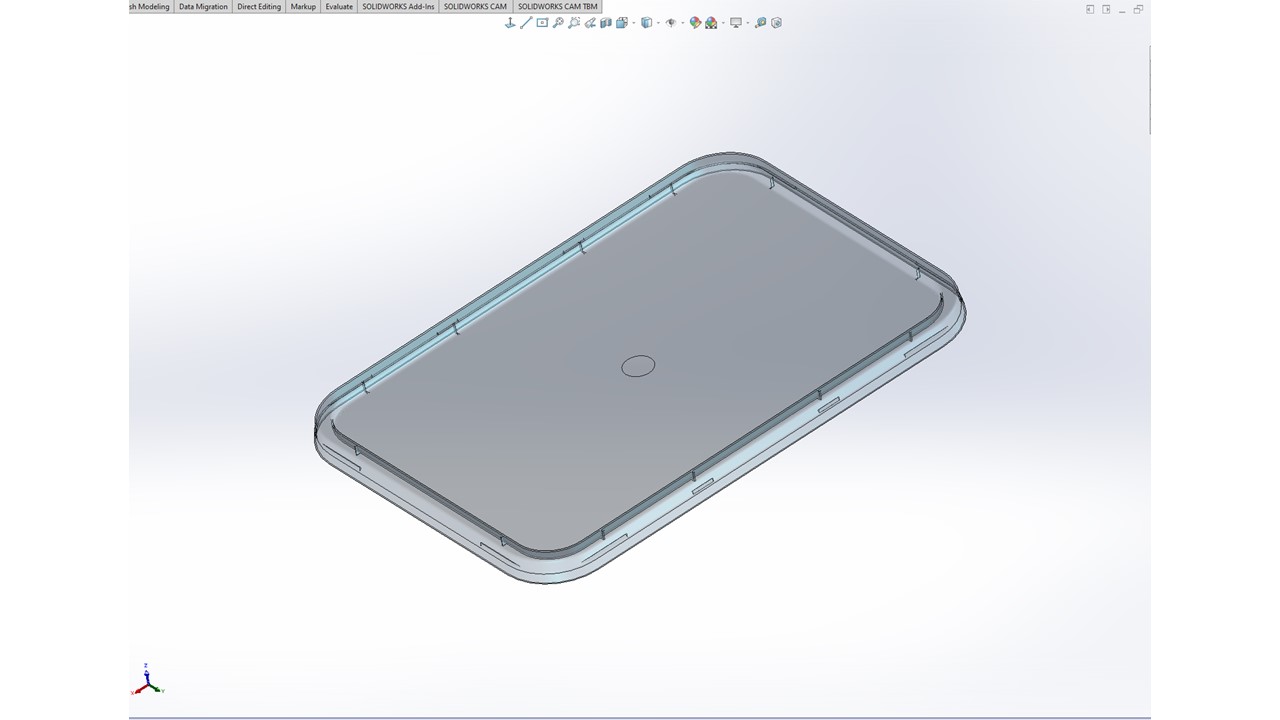

Food lid 0.40 wall thickness

Food lid 0.40 wall thicknessThe food lid had wall thickness variation of 0.12mm. After new mould design variation was within 0.02mm. Lid weight & flash also became easier to control in this 4 cavity mould.

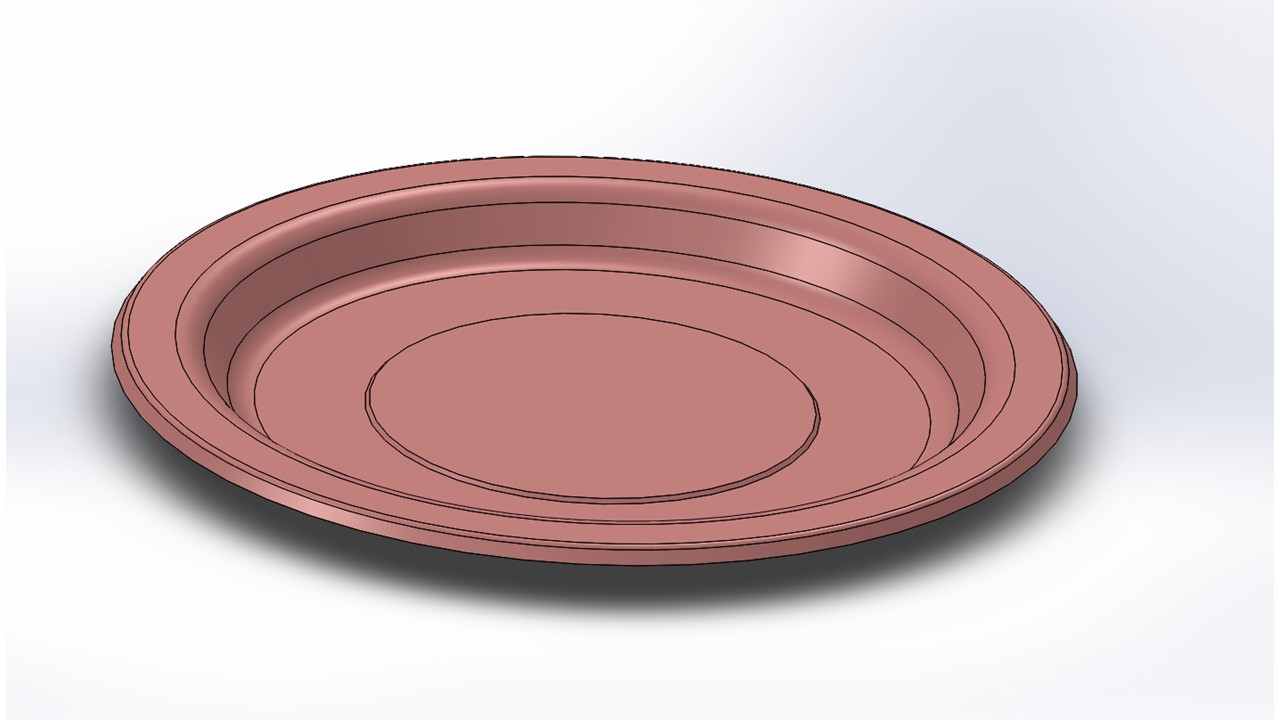

9 " plate 0.45 wall thickness

9 " plate 0.45 wall thicknessThe 9" plate 2+2 stack mold always had even wall thickness since the mould design was correct from the start.

Reasons For Uneven Wall Thickness in Injection Molding

Plastic parts with thin walls have such a narrow processing window that everything possible must be done to minimize uneven walls.

Here is a list of the most common reasons:

1. Poor moulding machine maintenance. Uneven tie bar stretch or dirty platens will not support the mould correctly under clamp & injection pressure.

2. Incorrect processing parameters. Using too much clamp or having the wrong fill time will put more stress on the mould.

3. Poor CNC machining of the mould components. All components must be machined within certain limits. High cavitation moulds will require tighter tolerances than single cavity moulds. Thinner walls also required tight machining tolerances (within 0.01mm). Poor machining could be due to operator or machine fault. If machine has been crashed at some stage in the past then often 1 of the axis could be misaligned enough to cut out of tolerance.

4. Poor mould fitting between cores & cavities. If locking taper is not correctly fitted then there will be movement between core & cavity. The quality of this step is dependent on the skill & knowledge of the individual toolmaker.

5. Finally, one of the most common reasons for uneven wall thickness is poor mould design.

When designing multi cavity moulds there is 1 rule I use which significantly reduces uneven wall thickness. Do this on your designs & you just might notice the difference especially in thin wall parts. In my experience, this applies equally to tall & skinny parts like a tub or short & flat parts like a lid.

I have designed hundreds of moulds and battled with uneven wall thickness for years.

Customers were constantly complaining about the issue.

I would discuss this issue with the machine supplier but they would consistently blame the mould design. ”It’s your mould, it’s not strong enough” they would say. When asked specifically what to do they would not give any helpful answer.

So, I thought maybe they are right. Maybe I needed to design the mould better. Maybe I needed to design the mould to suit each machine. The machine supplier never once told me to design a mould to suit a particular machine as they would be admitting a weakness in the moulding machine design. This would leave them open to liability. Instead, they just talk & talk & talk until you get sick of listening.

I decided to try a number of different mould designs over the next few years & eventually discovered a particular design concept which significantly improved wall thickness uniformity. I call it “mould design for better wall thickness”.

You too can add this simple design step to your next multi-cavity moulds.

If you are a mould maker or moulder suffering with uneven wall thickness & have eliminated all other possible reasons including the first 4 listed above then make contact using the form below to learn more. If you are pushing the limits on wall thickness such as 0.50,0.45,0.40mm or less then you need to know about this.

This is a chargeable service as it took time & resources to work out.

Upon receipt of payment, I will immediately provide you with a mould design layout to suit your specific moulding machines for your next project. “Mould design for better wall thickness” is a very simple but effect design modification which only the best mould makers use.

Better flash & weight control

Not only will it very likely improve wall thickness uniformity, it will also give you better flash & part weight control effectively increasing the processing window which is vital as machine & mould ages.

So why don’t you make your life easier & get this into your mould designs from now on and significantly reduce customer complaints. This concept can be used on all of your new moulds.

Can be used on existing Moulds

Mould design for better wall thickness” can be used on existing moulds but will require some rework as part of the mould will need to be re -made. However, there are other approaches to try first which are quicker to make but may not be as effective on existing moulds.

Contact Form

Add this design concept to your arsenal in your war against uneven wall thickness in injection molding.

If you are a mould maker, moulder or a recipient of plastic parts with uneven wall thickness & have eliminated the first 4 reasons listed above as possible causes then make contact using the form below to learn more. If you are pushing the limits on wall thickness then you need to know about this.

Return from Uneven Wall Thickness to Injection Mold Design

Return from Uneven Wall Thickness to Improve Your Injection Molding Home Page